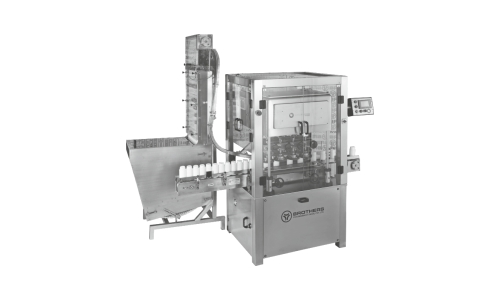

Capping Machine basically applies cap or lid to each container of liquid. Work of this machine is not only to apply and fit the cap but also to ensure that liquid does not get polluted by handling or sanitization. There are various types of capping machines available in the market.

We have different choices available for Bottle Capping Machine such as. single head capping machine, bottle ROPP capping machine, bottle screw capping machine, Jar Capping machine, pick and place bottle, vial capping machine, pick and place bottle capping machine, measuring cup placement machine, multi head vial capping machine, monoblock plugging and capping machine, lug capping machine, lug cap sealing machine, dosing cup placement machine, cap pressing machine, linear measuring cup placement, measuring, high speed automatic dosing, cup placement machine. Choose from our top selection of capping machines that best suit your requirement.

FAQ

We offer a wide range of labeling machines designed to meet the specific needs of the pharmaceutical industry. Our product line includes:

Labeling machines for bottles: Ideal for labeling round, oval, and square bottles of various sizes.

Labeling machines for vials: Designed for precise labeling of small vials used in pharmaceutical packaging.

Labeling machines for ampoules: Specialized machines for labeling ampoules, ensuring accuracy and efficiency.

Labeling machines for pouches: Suitable for labeling pouches and sachets used in pharmaceutical packaging.

Our labeling machines are equipped with advanced features to ensure accurate, efficient, and reliable labeling:

High-speed labeling: Our machines can label products at high speeds, increasing production efficiency.

Precision labeling: Our machines ensure precise label placement, preventing errors and waste.

Flexibility: Our machines can handle a variety of label sizes, shapes, and materials.

Durability: Our machines are built to last, with durable components and robust construction.

Our labeling machines can help you improve your pharmaceutical production in several ways:

Increased efficiency: Our machines can help you increase your production speed and reduce downtime.

Improved accuracy: Our machines can help you ensure accurate label placement, reducing errors and waste.

Reduced costs: Our machines can help you reduce your labeling costs by increasing efficiency and reducing waste.

Enhanced compliance: Our machines can help you comply with industry regulations and standards.

×

×