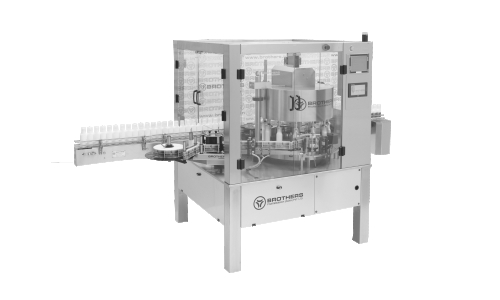

A Rotary Labelling Machine is an advanced equipment designed for high-speed and accurate label application on containers. Unlike linear labellers, rotary machines use a rotating carousel system that ensures consistent orientation and precision at high output speeds. These machines are especially preferred in industries where productivity, precision, and aesthetics are crucial.

Brothers Pharmamach is a leading Rotary Labelling Machine Manufacturer, Supplier and Exporter in India, offering advanced, efficient and high-speed labelling solutions for the pharmaceutical, food, cosmetic, and FMCG industries. With decades of engineering excellence and a strong presence in domestic as well as international markets, the company delivers precision-driven machines designed to meet the growing demands of modern production lines.

Our Rotary Labelling Machines are built with high-end automation, robust construction, and user-friendly controls, ensuring accuracy, efficiency, and reliability in every application. Whether you need to label round, square, oval, or custom-shaped bottles, Brothers Pharmamach offers complete solutions tailored to your manufacturing requirements.

FAQ

We offer a wide range of labeling machines designed to meet the specific needs of the pharmaceutical industry. Our product line includes:

Labeling machines for bottles: Ideal for labeling round, oval, and square bottles of various sizes.

Labeling machines for vials: Designed for precise labeling of small vials used in pharmaceutical packaging.

Labeling machines for ampoules: Specialized machines for labeling ampoules, ensuring accuracy and efficiency.

Labeling machines for pouches: Suitable for labeling pouches and sachets used in pharmaceutical packaging.

Our labeling machines are equipped with advanced features to ensure accurate, efficient, and reliable labeling:

High-speed labeling: Our machines can label products at high speeds, increasing production efficiency.

Precision labeling: Our machines ensure precise label placement, preventing errors and waste.

Flexibility: Our machines can handle a variety of label sizes, shapes, and materials.

Durability: Our machines are built to last, with durable components and robust construction.

Our labeling machines can help you improve your pharmaceutical production in several ways:

Increased efficiency: Our machines can help you increase your production speed and reduce downtime.

Improved accuracy: Our machines can help you ensure accurate label placement, reducing errors and waste.

Reduced costs: Our machines can help you reduce your labeling costs by increasing efficiency and reducing waste.

Enhanced compliance: Our machines can help you comply with industry regulations and standards.

×

×