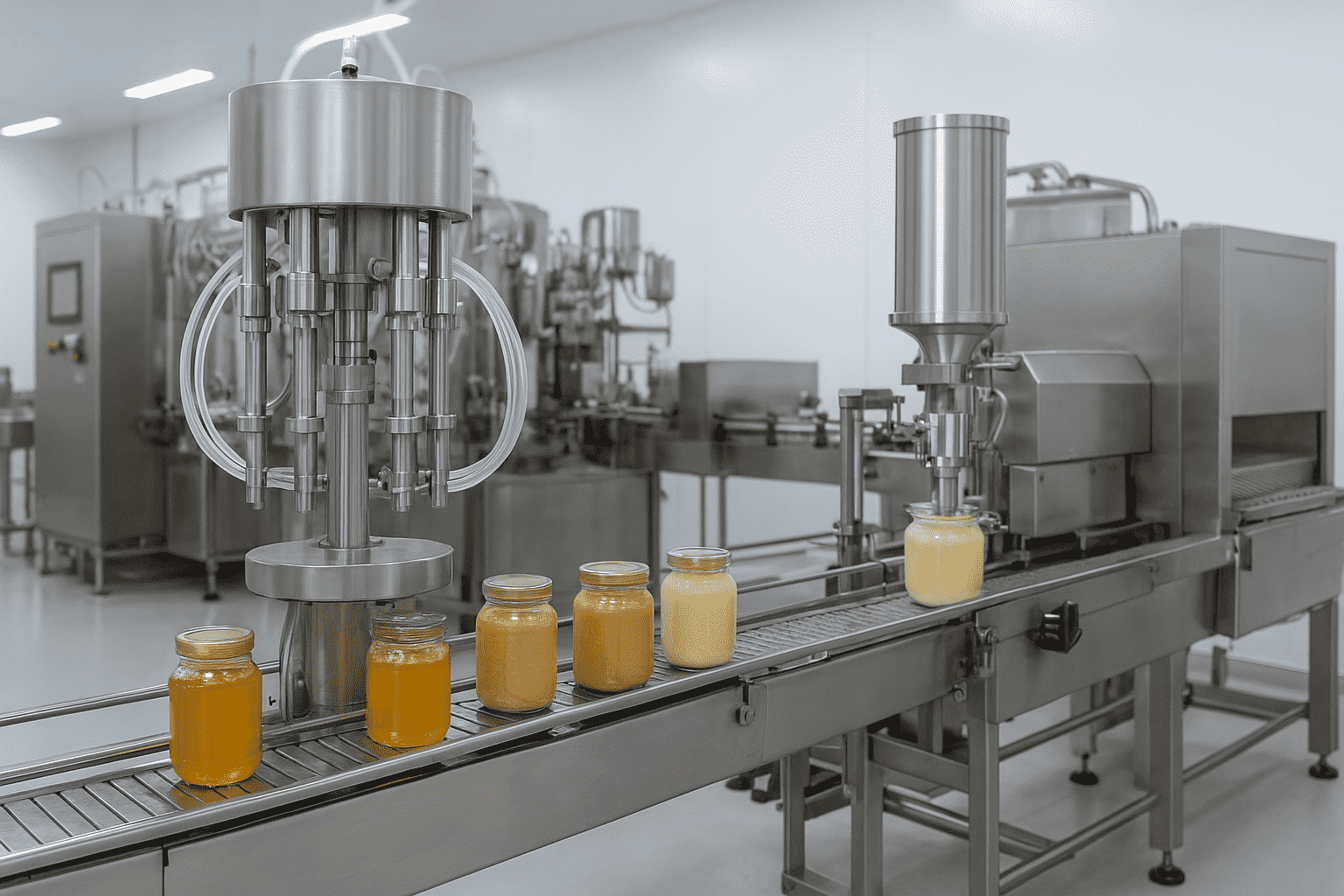

In modern packaging industries, efficiency and accuracy are the cornerstones of success. Whether you’re filling liquids, semi-liquids, or high-viscosity products, the right liquid filling machine can make all the difference. At Brothers Pharmamach, we specialize in advanced filling solutions designed to handle a wide range of products from honey and peanut butter to petroleum jelly and balm with unmatched precision, hygiene, and reliability.

The Role of a Liquid Filling Machine in Modern Production

A liquid filling machine is an essential part of any packaging line. It ensures consistent volume, eliminates product waste, and maintains production efficiency. Today’s industries demand flexibility a single machine capable of handling both free-flowing and viscous materials without compromising accuracy. That’s exactly what Brothers Pharmamach delivers: intelligent automation tailored to the product’s viscosity and texture. Our range of filling machines can be configured for different filling types, including volumetric, piston, and servo-based systems, ensuring smooth and consistent performance across all product categories.

Filling Solutions for Every Industry Need

-

Honey Filling Machine

Honey, known for its thick, sticky nature, requires precision and control during filling. Our honey filling machine is engineered with heated components and anti-drip nozzles to ensure smooth flow and accurate dosing. The system maintains hygiene while preserving honey’s natural texture and quality.

-

Peanut Butter Filling Machine

Peanut butter poses unique challenges due to its density and tendency to trap air. Our peanut butter filling machine uses piston-based technology with special agitators to maintain uniform consistency. It ensures clean, precise fills with no product wastage — ideal for jars, bottles, and tubs.

-

Balm Filling Machine

When filling semi-solid products like balm, temperature control becomes critical. Our balm filling machine is integrated with a cooling tunnel for balm, which helps solidify the product after filling. This ensures smooth texture, perfect shape, and leak-free sealing, making it ideal for cosmetic and pharmaceutical industries.

-

Petroleum Jelly Filling Machine

Petroleum jelly requires gentle handling to maintain its structure. Our petroleum jelly filling machine is designed for controlled temperature filling to avoid air entrapment and maintain uniformity. Paired with a cooling tunnel for petroleum jelly, the system delivers clean, stable, and well-formed containers ready for labeling and packing

-

Mayonnaise Filling Machine

Mayonnaise is delicate, emulsion-based, and temperature-sensitive. Our mayonnaise filling machine ensures smooth transfer through hygienic stainless-steel pipelines and specialized valves that prevent product separation. The system supports both glass and plastic container applications with precision dosing.

-

Hot Wax Filling Machine

Filling molten wax requires accuracy and safety. Our hot wax filling machine features advanced heating control systems and insulated pathways to maintain a consistent temperature during the entire filling process. It’s an excellent choice for candle, cosmetic, and skincare product manufacturers.

The packaging world demands innovation that combines speed, safety, and precision. With our advanced liquid filling machines, you can fill any product from honey and peanut butter to balm and petroleum jelly with absolute confidence.

At Brothers Pharmamach, we don’t just build machines — we create complete, intelligent solutions that empower your production line to perform at its best.

Elevate your packaging with Brothers Pharmamach where every drop counts.

Recent Blog

- Advanced Liquid Filling Machines for Viscous and Semi-Viscous Products

- Revolutionizing Labeling: The Power of Wet Glue Labeling Machines

- Efficient and Accurate: The Advantages of Sticker Labeling Machines

- Precision Filling: Optimizing Dry Syrup and Powder Packaging

- Ensuring Quality and Efficiency: Capsule Filling Machine Solutions

- The Future of Packaging: Trends and Innovations

- The Future of Packaging: Sustainable and Innovative Solutions

- Inspection Machine Solutions for Pharmaceutical Packaging

×

×